ReNu Surface Shield is the leading specialist in VCT (Vinyl Composition Tile) stripping and waxing services, serving both businesses and homeowners in the Greater Richmond, VA area for all their floor care needs! With our flawless reputation, customers can trust that their floors will be treated with the utmost care and precision, ensuring the job is done right the first time. We are a locally owned and operated family business, fully licensed, insured, and certified in every aspect of our trade. Plus, our owner brings decades of hands-on experience. At ReNu Surface Shield, we’re dedicated to enhancing your home or business with cleaner, more efficient spaces through expert floor care. Call us today to discuss your next VCT stripping and waxing project, or any other deep cleaning, sealing, and restoration services!

Why Does VCT Need to Be Stripped & Waxed?

Over time, vinyl floors can become stained from dirt and foot traffic, and standard finishes tend to yellow as they age. Additionally, vinyl can be quite slippery when wet, posing a safety concern. Unlike harder materials like stone or tile, vinyl is a softer, more resilient composite, making it more susceptible to scratches and other abrasions. As a result, flooring types like VCT, LVT, LVP, sheet vinyl, and welded seam vinyl all require significant upkeep to maintain both their functionality and appearance.

Stripping & Refinishing Vinyl Composite Tile Floors

Stripping and refinishing is the traditional method for maintaining vinyl floors. However, this approach can be expensive, time-consuming, and disruptive, and it often produces toxic waste. A large portion of the stripped material is considered hazardous and requires proper disposal. Additionally, the finishes applied during this process tend to yellow over time, and regular refinishing is necessary. In many cases, this involves a lengthy, multi-step process with up to seven coats of finish.

In some instances, urethanes are used to seal vinyl floors. While effective, this method is costly, and stripping or refinishing urethane coatings demands significant labor and material investment. Furthermore, repairs are challenging to blend seamlessly with the existing finish.

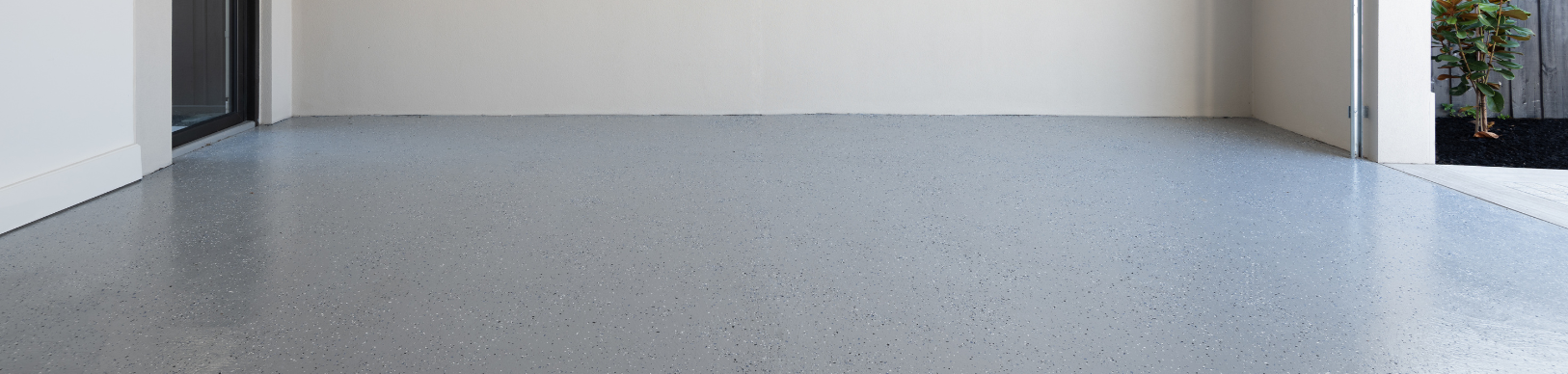

VCT Restoration

Our vinyl restoration system uses a single-coat application process, eliminating the need for burnishing or buffing during or after installation. This thin yet highly durable coating offers exceptional wear resistance without the need for stripping. Over time, it can be easily repaired in high-traffic areas, with repairs blending seamlessly to maintain an immaculate appearance. There’s no unsightly buildup along walls or corners. Compared to traditional stripping and refinishing or urethane applications, this method is faster and provides long-lasting results.

1) Bonding and Flexibility. The vinyl restoration system creates a strong, flexible bond with the vinyl substrate, matching the resilience of the tile. If heavy furniture, such as a desk or chair, is placed on the treated floor, the coating will flex and contour to the vinyl, then bounce back to its original shape without delaminating.

2) Slip Resistance. The slip resistance of this system is impressive, with a wet slip coefficient of 0.75. In contrast, standard vinyl has a slip coefficient of less than 0.5 when wet, making the treated surface much safer to walk on.

3) Avoid Yellowing and Dirt Stains. Unlike other coatings, this system repels dirt and prevents absorption, meaning it won’t show dirt stains. The material is inorganic, so it resists yellowing over time, maintaining a clean, polished look.

4) Abrasion Resistance. The restoration system is highly abrasion-resistant due to its silica compound or ceramic formulation. This makes it incredibly tough, ensuring that it can withstand heavy wear and tear without showing signs of damage.

How the VCT Strip & Wax System is Applied

1) Preparation: All pre-existing coatings, including manufacturer finishes, must be completely removed using traditional stripping methods, which involve abrasion and stripping chemicals. Adjacent surfaces should be protected, and the floor must be thoroughly dried.

2) Buffing: To improve surface tension and maximize gloss and uniformity, the floor is buffed before applying the coating.

3) Application: The restoration product is applied as a single coat, using a specific technique tailored to the conditions of the job site.

4) Curing: Light traffic can be allowed within one hour of application, but a full cure takes about three days. During this curing period, only water should be used for cleaning.

Maintenance for VCT Floors

1) Simple Care: No harsh brushes or chemicals are required for cleaning.

2) Ongoing Cleaning: Regular, light cleaning will suffice. For the best maintenance, we recommend using a specialized cleaner like Safety Clean or a neutral floor soap with a mild disinfectant. The coating is resistant to most cleaning agents, so there’s no need for harsh, toxic chemicals.

3) Warranty: When applied and maintained properly, the system is backed by a five-year warranty, protecting against yellowing, delamination, and premature wear.

VCT Stripping & Waxing in Midlothian, Bon Air, Manchester, Chesterfield, Mechanicsville, Henrico and Greater Richmond, Virginia

Our vinyl restoration system provides a long-lasting, efficient solution for maintaining vinyl floors while reducing the need for frequent, costly refinishing. Call Renu Surface Shield for VCT stripping and waxing and related services today!